A-550 is equipped with vacuum test system to increase the element test range. The detector is equipped with the test system of SDD to detect the elements between ores and reduce the interference betwe

全国服务热线: /

在线咨询Application fields:

1. RoHS / halogen free test instruction

2. Alloy analysis (especially light elements)

Composition analysis of Zn Al alloy

Composition analysis of aluminum alloy

Determination and composition analysis of Tonghe gold medal

Composition analysis of stainless steel (vacuum light element detection)

Composition analysis of cast iron, etc

3. Analysis of coating composition

film analysis

Environmental protection test of coating

4. Packaging directive test standard (94 / 62 / EC)

CD+PB+Hg+ Cr6 <100

5. Testing standard of toy directive

6. Analysis of ore composition

1.5. Working conditions:

Working temperature: 15-30 ℃

Relative humidity: 40% ~ 70%

Power supply: AC: 220 V ± 5V、

1.6. Technical performance and index:

1.6.1. The range of element analysis is from sodium (NA) to uranium (U);

1.6.2. The analysis range of element content is 1ppm to 99.99%;

1.6.3. Measurement time: 100-300 seconds (adjustable);

1.6.4. The detection limit of harmful elements (CD / Pb / Cr / Hg / BR / CL) specified in ROHS directive is up to 1ppm;

1.6.7. The energy resolution is 129 ± 5 EV;

1.6.8. The temperature range is 15 ℃ to 30 ℃;

1.6.9. Power supply: AC 220 V ± 5V (AC purified regulated power supply is recommended);

1.7. Product features

1.7.1 A-550 is equipped with a vacuum test system to increase the element test range. The detector is equipped with a test system of SDD to detect the elements in the ore room and reduce the interference between elements

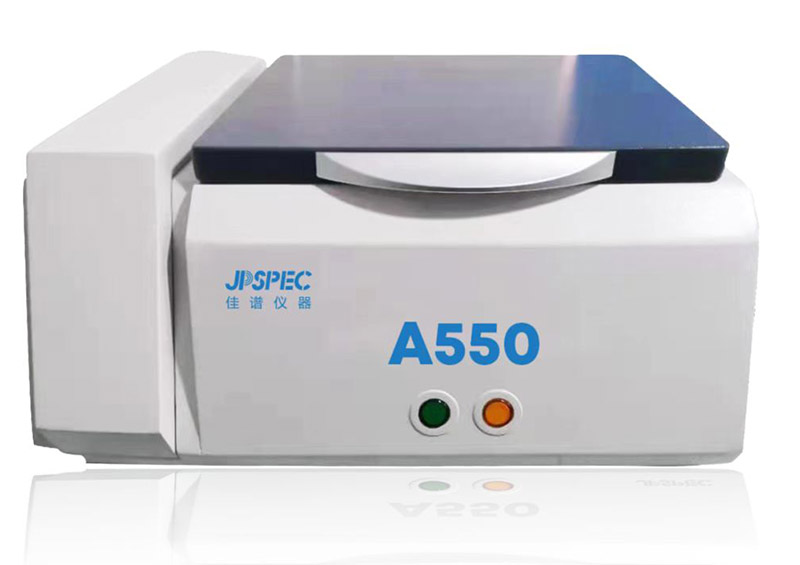

1.7.2 the overall structural design makes the instrument beautiful and elegant.

1.7.3 it adopts the latest silicon drift detector in the United States, electric refrigeration instead of liquid nitrogen refrigeration, with small volume, accurate data analysis and low maintenance cost.

1.7.4 self developed SES signal processing system (digital multi-channel) is adopted to effectively improve the peak to back ratio and make the measurement more accurate.

1.7.5 one click automatic test makes it easier to use, more convenient and more user-friendly.

1.7.6 seven kinds of optical path correction and collimation systems are automatically switched according to different samples.

1.7.7 multiple anti radiation leakage design, radiation protection level belongs to the highest level of similar products.

1.7.8 optimize the integrated heat dissipation design to greatly improve the heat dissipation performance of the whole machine and ensure the operation safety of X-ray source.

1.7.9 the unique movement temperature monitoring technology ensures the safe and reliable operation of the radiation source, effectively prolongs its service life and reduces the use cost.

1.7.10 multiple instrument accessories protection system, and the whole process monitoring can be carried out through software, making the instrument work more stable and safer.

1.7.11 special vacuum test software, whether vacuum can be freely selected, vacuum degree can be displayed in real time, standard window design, friendly interface, easy operation, all control are between the mouse.

1.7.12 the USB2.0 interface is adopted to ensure the accurate, high-speed and effective data transmission.

1.7.13 the unique automatic vacuum system can completely shield the influence of air on light element test, greatly improve the detection limit of light element, and expand the detection range.

1.7.14 the integrated vacuum chamber design effectively ensures the vacuum degree meeting the test requirements and improves the maintainability of the equipment.

1.7.15 it is easy to switch between vacuumizing test and non vacuumizing test, which is convenient for customers to use; At the same time, the vacuum can be removed by opening the cover, which is safe, simple and practical.

2. Main configuration of instrument hardware

2.1 electric refrigeration detector:

2.1.1; Resolution: 145 ± 5e ev

2.1.2. Amplifying circuit module: detect the sample characteristic X-ray; Further amplify the information collected by detection.

2.2 X-ray excitation device:

2.2.1. Maximum filament current output: 1mA;

2.2.2. It is a semi loss type component with a service life of more than 5000 hours

2.3 high voltage launcher:

2.3.1. Maximum output voltage: 50kV;

2.3.2. Minimum 5kV controllable regulation

2.3.3. Built in voltage overload protection

2.4 integrated vacuum system

2.4.1 vacuum pump system with low vibration, low noise, self-protection and fast pumping speed;

2.4.2 geometric pumping speed: 60 L / min (50 Hz)

2.4.3 ultimate pressure: 6.7 × 10-2 Pa

2.5 digital multichannel analyzer:

2.5.1. Convert the collected analog signal into digital signal, and provide the processing results to the upper computer software;

2.5.2 maximum number of channels: 4096;

2.5.3 includes signal enhancement processing function;

2.65 optical filter module

2.6.1 reduce the interference in the process of X-ray transmission to ensure that the detector receives the signal accurately;

2.6.2 integrate the collimator with the filter;

2.7 collimator automatic switching module

2.7.1 there are up to 7 choices, with caliber of 8-1, 8-2, 8-3, 8-4, 6, 4 and 2 respectively.

2.8 filter automatic switching module

2.8.1 free selection and switching of five filters.

2.9 free combination module of collimator and filter

2.9.1 free combination of dozens of collimators and filters.

2.10 automatic selection module of working curve

2.10.1 automatic selection of working curve, abandoning manual selection, avoiding manual operation error, and realizing automation and intelligence

The interpretation is more perfect, making the operation more humane and more convenient.

3. Special software JPSPEC-FP

3.1.1 software introduction

It is specially developed for the detection of elements in metal materials (including vacuum control function). It processes and calculates the collected spectral signals, and reports and displays the measurement results.

3.1.2 function introduction

The measurement time is 100-300 seconds (adjustable) for the adjustable data of different mineral materials

Simple and intuitive operation interface, easy to use, no need for professionals to operate

3.2 the software interface is shown in the figure below:

Suitable calibration curve can be selected automatically, which makes the measurement more convenient and accurate

The interface between Chinese and English is automatically switched, and the third-party language customization function is provided

Automatic calibration instrument

The qualitative analysis of sample material is provided to prevent manual user from selecting wrong curve

Various report forms printing

Multiple spectrograms can be displayed at the same time

Real time display of instrument test parameters and vacuum degree, all control at a glance

The unique movement temperature monitoring technology ensures the safe and reliable operation of X-ray source, effectively prolongs its service life and reduces the use cost.

4. Sample configuration

The standard sample is used to make working curve

4.1 sample chamber

Open large sample cavity: 610mm × 320mm × one hundred × Semi closed sample chamber (when vacuumizing) Φ 100mm × h75mm

4.2 standard sample

Silver correction film

5. Standard accessories

Low noise fast pumping vacuum pump

Small size, light weight, simple structure, easy maintenance and repair

Fast pumping speed, 20s can meet the requirements of vacuum test

The limit pressure can reach 6.7 × 10-2Pa

Single phase AC220V power supply, without external three-phase power supply

6. Product warranty and after-sales service

6.1 provide free training for customer's operators.

6.2 the installation, commissioning, acceptance, training and technical services of domestic customers are free of charge, and the operators are trained on the user's site( Foreign customers can solve it through negotiation)

6.3 normal use, after the company's after-sales service department technical personnel confirmed that the fault is caused by process or material defects, and has not been disassembled and repaired, the instrument host is guaranteed for one year from the date of acceptance.

6.4 product life-long maintenance (customers must fill in detailed and true valid purchase certificate, invoice and warranty card, etc.).

6.5 free software upgrade.

6.6 provide the most effective technical service, respond within 2 hours after receiving the user's fault information, and send someone to repair and remove the fault within 48 hours if necessary.

JPSPECamjs澳金沙门公众号

JPSPECamjs澳金沙门公众号

amjs澳金沙门线路首页二维码

amjs澳金沙门线路首页二维码